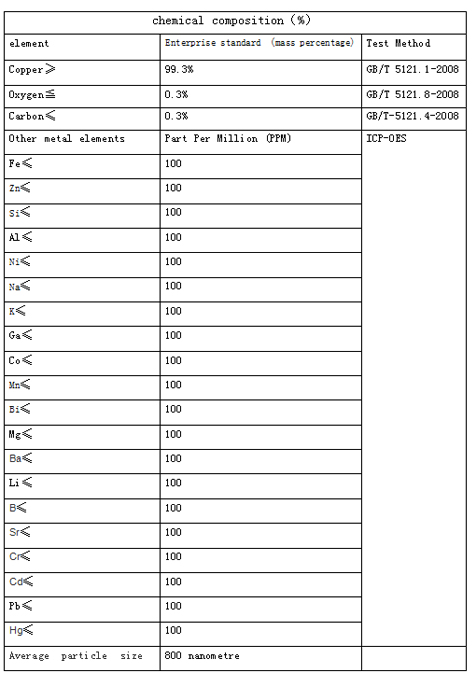

|

Specification of Ultrafine Copper Powder

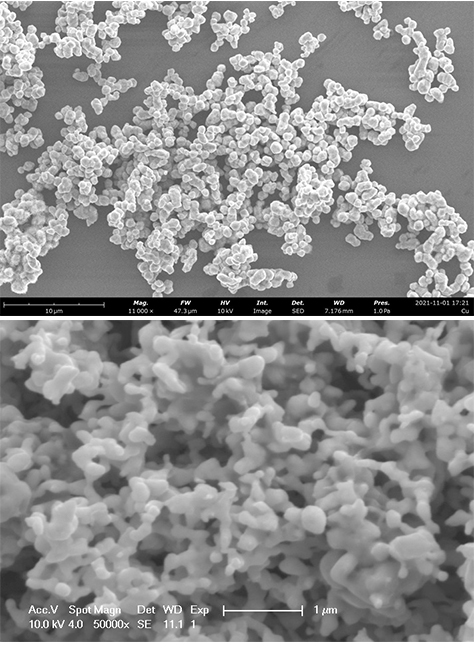

SEM

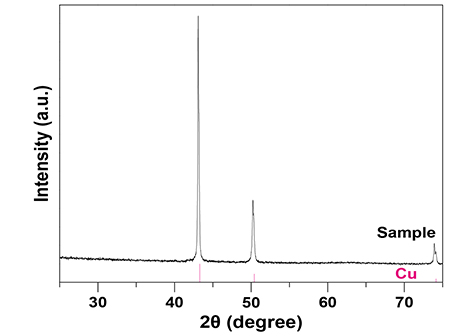

XRD

1. Conductive paste. The conductive paste is widely used in the microelectronics industry, wiring, packaging, connections, etc., plays a vital role on the miniaturization of microelectronic devices. The conductive paste made of nano-copper powder has excellent performance and can be used in chip multilayer ceramic capacitor (MLCC), wafer ceramic capacitor, varistor and other electronic components electrode instead of silver paste, which can greatly reduce the production cost. 2. Antibacterial and mildew resistant materials. Nano-copper powder is widely used in chemical fiber, plastic, rubber, coating, glue and other polymer materials on antibacterial and mildew. 3. High thermal conductivity fillers. Adding nano-copper powder to the epoxy resin, organic silicone rubber, engineering plastics, coatings and other polymer materials can greatly improve the thermal conductivity of polymer materials. 4. Lubricating materials. Nano-copper powder can be added to the lubricating oil to change the mechanical friction properties, and can also repair the microscopic defects of the friction surface. 5. Activated sintering agents. Nano-copper powder is an effective sintering additive, which can greatly reduce the sintering temperature of powder metallurgy products and high temperature ceramic products, and can be used as the binder of diamond and ceramic cutting tools. 6. High efficiency catalyst. Due to the large specific surface area and high activity, nano-copper powder has strong catalytic effect. Using nano-copper powder instead of conventional copper powder can greatly improve the catalytic efficiency and conversion rate, which can mainly be used for industrial water gas preparation and methanol production. |